Agricultural Utensils Accessories Tiller Blades

Classification And Characteristics

The classification and characteristics of the tiller knife group

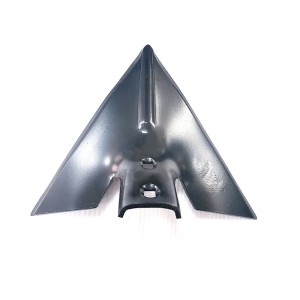

01 Deep tillage knife set

The deep tillage knife set is also called deep tillage hoe. Its blade is a chisel-shaped knife. It is mainly used for deep loosening of dry land with less weeds.

02 Dryland tiller set

According to the number of blades installed in each group of cutterheads and the number of groups of cutterheads, there are three-piece and four-group dryland-knife groups, four-piece and four-group dryland-knife groups and other specifications. Its blade is a right-angle knife. The four-piece and four-group dryland tiller group has a larger load than the three-piece four-group tiller group. Mainly used for dry land, dry land, sandy land, wasteland, greenhouse operation, etc. with soft soil.

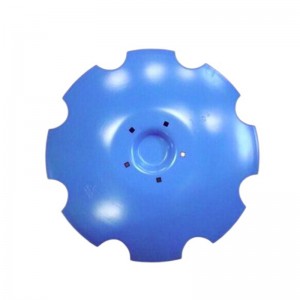

03 Wetland Scimitar Knife Set

The wetland cultivating knife group includes a composite machete knife group, etc. The blade is a machete. On the basis of the wetland machete, a weeding blade is equipped, and a compound machete of different specifications is formed according to the number of machetes in each group of cutter heads. The Wetland Scimitar Knife Set is mainly used for rotary tillage in wetlands with less weeds or paddy fields with hard mud feet. The compound machete cutter set is used for rice pile fields with hard mud feet and wetlands with soft soil or shallow paddy fields and blisters with weeds. In addition, the wetland machete set can also be used for dry land farming with soft soil. However, it is recommended to choose suitable cutter sets according to different soils, which can not only obtain good farming quality but also reduce the damage of cutters.

Details

According to the power, ploughing width and ploughing depth of the supporting unit, the cutter group is selected. Generally speaking, the larger the rotation diameter of the cutter group, the deeper the ploughing depth, the greater the power consumption, and the larger the ploughing width of the blade group, the greater the power consumption. In addition, factors such as the maximum torque that the gearbox body gears can withstand should also be considered. Since there is no more practical theory for force analysis of the cutter group, for the manufacturer of the supporting unit, the cutter group should be selected according to the design experience or experimental research.

Product Display